Being a brief history of the development of Llwyd's Machine

Llwyd and his Mk I and Mk V versions of the Machine

Don Tivar's Original Machine

A full discussion of Tivar's machine can be found at http://moondragon.info/wiki/The_Machine.

Llwyd's Machine - Mark I

In order to perform my own tests, I decided to build my own machine. Tivar had used metallic bar stock as that was what he had lying around available as scrap. The shop in my house has lots of scrap wood, so that was the route that I took, although the core mechanism is the same.

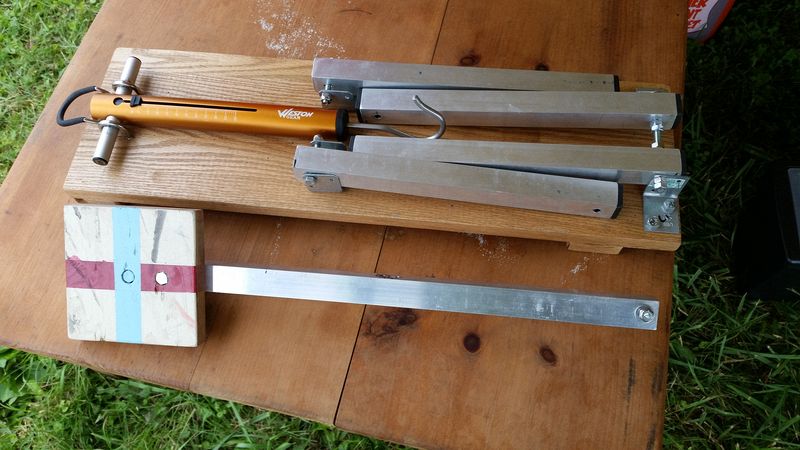

The Machine all folded up for transport

Legs unfolded and pivot arm set aside. The red on the base was there from its previous life. It is not blood.

A sabre saw blade is used as a ratchet.

I bought both an analog and a digital fish scale.

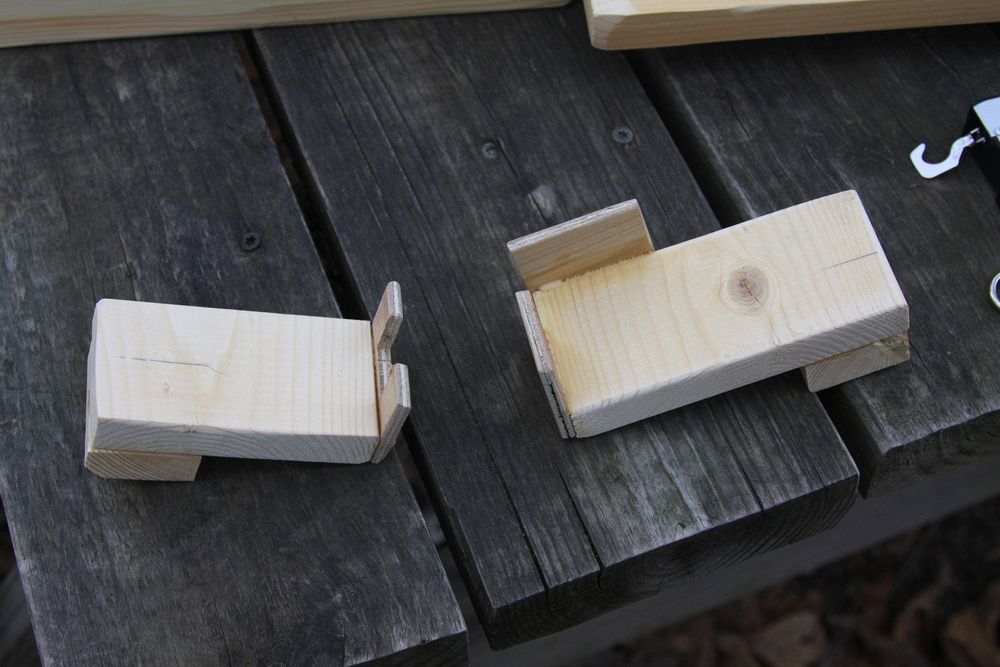

Which required different mounting blocks because their pulls were in different spots. The digital scale ended up not being useful as it (a) had no significant draw and (b) despite having the capability of locking its display at the maximum load, that load had to be steady for a second or so before it would lock.

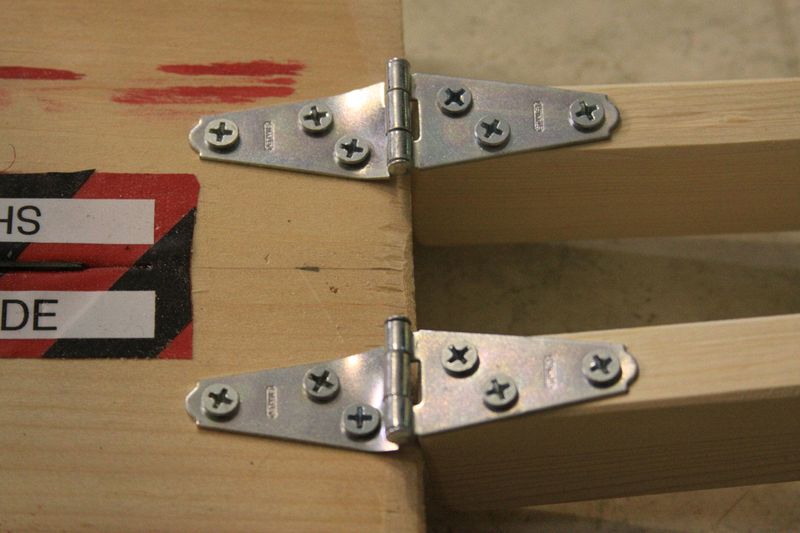

Detail of the assembled machine. A hinge is attached to the bottom of the rotating arm. This engages with the saw blade below and locks the arm at its maximum deflection so the fish scale can be read at your leisure before the machine is manually reset.

At the moment, the target is a 5" by 5" piece of plywood. I'm unsure how sturdy this will be. I have thoughts of putting padding on the surface to better resemble striking a person in armor.

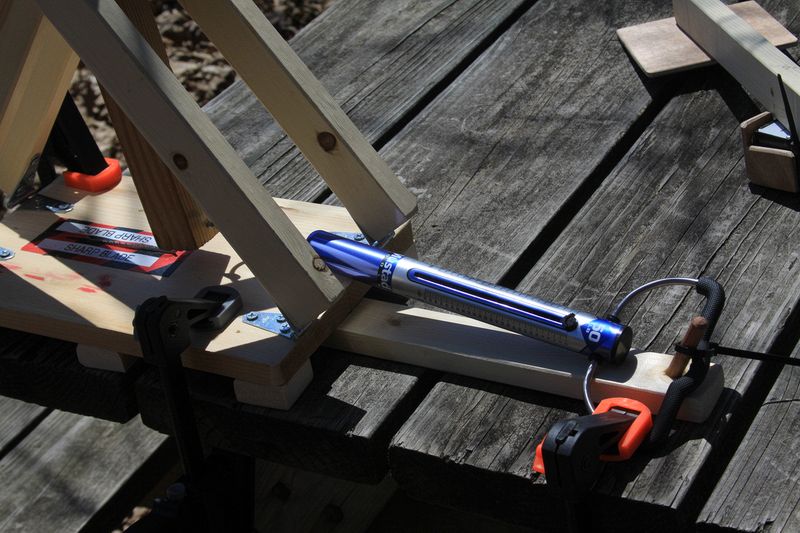

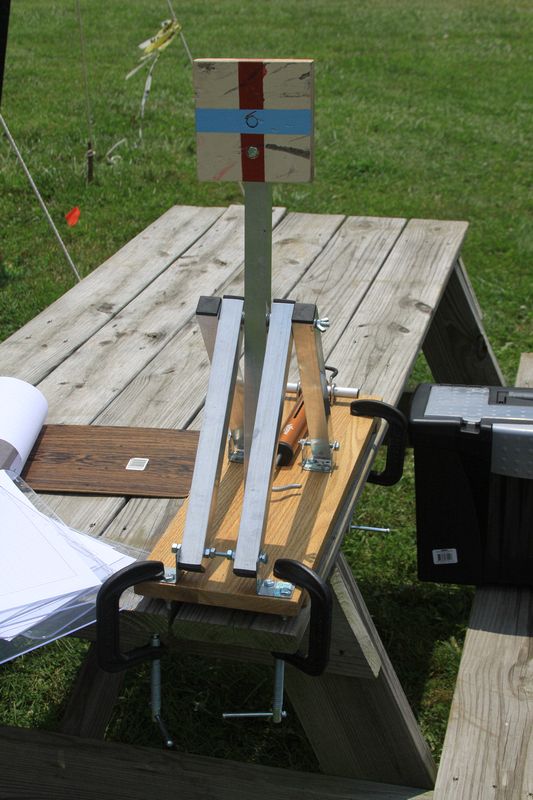

A clamp is used to attach the machine to a heavy picnic table. After testing we decided we needed more than one clamp and 2 more were purchased.

An initial test with a two handed sword.

The First Test

One brief test was first performed at a local practice. The Atlantian Earl Marshal, Sir Otto, was present. The digital scale was a failure. Having only one clamp to the table was an issue. And the mounting block for the analog scale was inadequate and incorrectly posititioned for good readings. Also, the cup hook on the arm had a real issue with disconnecting from the hook on the scale.

The Second Test - Mark II

All of these issues were addressed and a second round of testing is performed on March 29 at Defending the Gate.

On an extremely rainy and muddy Saturday, the machine was set up for its next test. We determined that the design issues discovered in the first test had been addressed, but that the scale itself was inadequate. We were topping out its 28 pound load with most strikes. (The ratchet system actually only allowed a maximum of 25 pounds to be recorded before the arm rotated too far.)

And we also managed to unroll the replacement eye screw into a straight piece of metal:

That was an eye screw on the right.

So, before we proceeded to actual data collection, a beefier eye screw was needed as well as a scale with a higher range.

First Data Collection - Mark III

The new 50 pound capable scale has a slider that marks the maximum force it measured. This removed the need for the ratchet system. Since I was building a new, sturdier, arm anyway, I left off the hinge on the new arm.

An extension was added to the base to support the larger scale.

The updated machine mounted for testing.

Machine Mk III Postmortem

Following the first round of data collection, I again reviewed my design and identified a number of issues. First, the 50 pound scale had a serious design flaw for our use. The handle's seam was inside the scale, just above the core shaft of the spring. It apparently was not welded together. The impact of our hits bent the handle and separated the two halves allowing the shaft to shift and blow off the cap. The scale was never the same afterward.

Also, the hinges on the front of the machine showed some bending.

Finally, the single post attachment for the scale was a poor choice.

Machine Mark IV

So, more changes were made to the machine. The bent hinges were gently hammered back into shape. I expect I'll have to rebuild the base of the machine after its next use and before Pennsic. I'll see if I can get some sturdier hinges. I've removed the saw blade but have left the warning tape in place for now.

A new 100 pound scale was purchased. The handle on this one seems to be a better design.

There was a calibration question regarding the 50 pound scale which was made after its destruction. So, I did a little informal calibration of the new scale. My wife has a "portable" anvil. The new 100 pound scale reports that it weighs 13 pounds. As you can see in the picture below, it is hard to read the scale with more precision than 1 pound. My household bathroom scale also reports that the anvil is 13 pounds. The digital scale shown near the top of this page reports that the anvil is 14.6 pounds. So, the new scale is doing pretty good, but may be reading a little lighter than is really the case.

For the Mark IV machine, I held the scale down to the base with 2 u-bolts.

After a brief test run at our local practice, I made a small modification to the Mark IV (creating the Mark IV-A) machine. I did not have long enough u-bolts on the end of the scale; I was only grabbing about 1 thread on each end. After a failed attempt to countersink holes for the nuts, I replaced the whole secondary deck with a thinner plywood deck that allowed the nuts to get completely onto the bolts' threads.

Second Data Collection

Memorial Day weekend is one of Atlantia's biggest events, Ruby Joust. So, I brought the new Mark IV-A machine, my new Alchem spear (that arrived 2 days before the event) and went in search of a wider sample of fencers. I ended up recording 195 data points from 11 different people of varying size, strength, gender, and skill levels. After collecting data from fencers, I moved onto collecting data from some armored fighters to represent what cross-over fighters might do. I was sucessful in collecting data from one Knight, but the first unbelt to hit the machine broke it, so we were done for the event.

I was unable to locate a suitable picnic table, so I attached the machine to a counter in one of the on-site buildings. This ended up forcing most fencers to strike slightly upward, as if hitting their opponent in the face.

The combined impact of 250-ish hits (including those that hit high or low and were not recorded) caused the machine to slowly shift. I reset the hold-down clamps once, but eventually they were enough off center than a spear strike broke two of the (cheap!) clamps and released the machine from the counter. This in turn sheared the main deck at the attachment to the extension arm:

Both the glue and the screws held. The board itself sheared at the joint:

The front hinges were where I expected the failure to occur. They did indeed bend excessively, but held on:

The 5x5" target of thin plywood also showed some thin cracks on the face. I am very impressed that it has survived perhaps 500 hits over the full development and testing of the machine.

The Mark V Machine

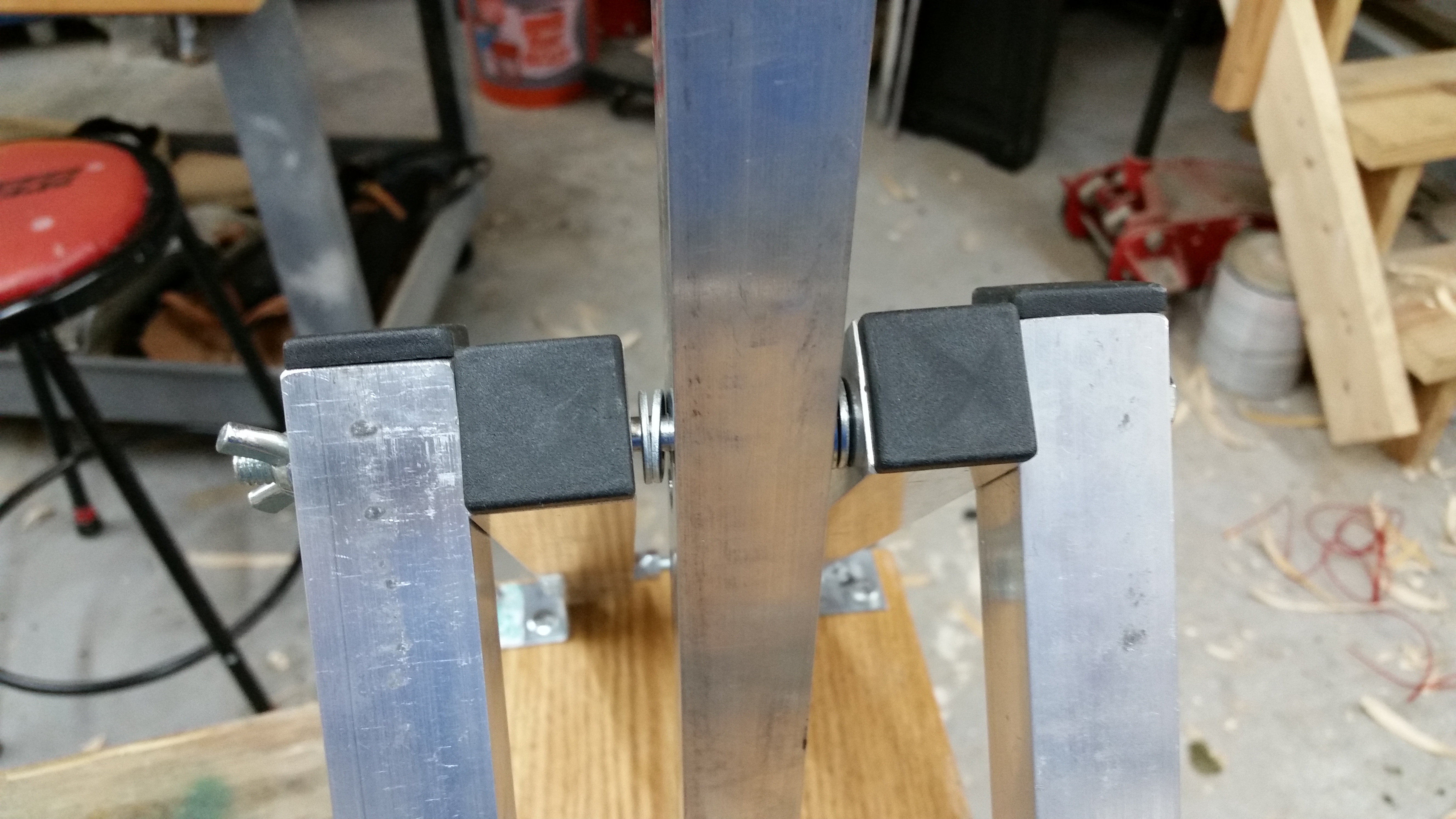

The Mark V version of the machine started from scratch. The 100lb scale is the same as before, but all the other parts are new. The design is the same, but the base has been replaced with a single piece of 3/4" oak and the structure and pivot arms are 1" square aluminum tubing. The target is also 3/4" oak. For this version of the machine I moved constuction from my own home shop to that of Jarl Timoch Hakonson. Timoch was extremely helpful and creative in producing a significantly stronger version of the previous design.

Here are a few pictures of it under construction:

The front legs share a single long bolt for a hinge. The rear legs have separate, shorter bolts as hinges so that the scale can be positioned between them.

Slightly smaller ubolts were used for the scale and rubber caps were purchased to cover most of the open ends of the tube, as seen on the upper pivot hinge. This hinge is the only one designed to be regularly removed. Once removed the machine folds for much easier transport.

The base and back of the target were polyurethaned. The face of the target was painted with a 1" tall red stripe across the center. For a shot to be counted it must contact the red stripe, even if part of the blunt is outside the stripe area. That means the center was missed by less than 1" vertically.

Testing the Mark V machine

We did initial testing of the Mark V machine at a local fighter practice on July 13, 2014. It mostly passed with flying colors. It even survived spear strikes from the unbelted fighter who delivered the killing blow to the Mark IV predessor machine (and who set a new record of 87 pounds with a "combat speed" blow.) We collected a small amount of new data, including calibration confirmation strikes from Llwyd. The forces and ratios of different weapons' forces were consistent with previous 100 lb scale results. I will include the new results in my post-Pennsic data dump as part of the Atlantian data.

Lord Aiden delivering a test spear strike. Also, the nut in the spear's tip apparently shifted and allowed the spear to penetrate the supplied tip. I replaced the tip (and nut) with a new one and we continued testing.

Two problems were encoutered in the test. First, the new C-clamps were just barely large enough to go around the thick picnic table, the oak base and the 3/4" thick feet. Slightly larger clamps are needed for general use. Also, the single bolt at the center of the target allowed it to spin (previous versions were glued and screwed.) A second bolt will be added prior to Pennsic testing.

No visual damage was noted on any part of the machine beyond a few skid marks on the target square. So, after addressing the two problems above, I'm hopeful that we'll be able to put the machine to extensive use at Pennsic in a few weeks.

Pennsic 43 - Mark V in Use

I spent more than 12 hours over 4 days collecting data on the rapier field at Pennsic 43. I talked to scores of people, showed off the machine to the SEM, SRM, some DSRMs, many KRMs and a few KEMs as well. And I collected force data from about 60 people from around the world. As you would expect, the largest percentages of people were from the hosting Kingdoms, but I did manage to get 2 friends from Lochac to hit the machine as well as a few from other distant Kingdoms.

The Mark V machine broken down for transport prior to use.

A minor rotation error during the addition of the second bolt to the target resulted in the previously horizontal red stripe becoming vertical. A new blue stripe was added to address the problem. It is 1" tall. We asked our subjects to report if their strikes contacted the blue stripe (it did not have to be entirely within it) or was too high or low. Only strikes that contacted the strike were recorded. This reduced the possible error due to moment arm differences to about +/-1 inch for a normal sword tip.

My son was a big help as a scientific minion.

Also, the RMiC, Don Caine, was extremely supportive and helpful in loaning me one of his picnic tables.

Damian from Lochac trying his hand with an Alchem spear.

Alchem also gave me a less stiff version of the spear blade to try. I have tipped it, but did not have a chance to mount it in the spear to try. I hope to do that soon.

Counting ranging shots and off target hits, I estimate that the machine took at least 6000 strikes during Pennsic. These ranged up to 90 pounds. The only visible damage to the Mark V is the paint on the target. I had to add the sharpie lines at the midway point in testing so that people could see the target blue stripe. I will probably redo the paint entirely before its next use - whenever that may be - and return to a single horizontal red stripe.

2016 World Tour

Following the publication of the Pennsic 43 data, about a year and a half passed with no further testing. Then, the new Society Marshall and the Society Rapier Marshall created an advisory committee on updating the SCA rapier rules. One of their mandates was to research or test to produce hard data that supported our armor, blade, and other standards. I assembled a modern and a society resume and applied for the committee. I was one of 20 chosen (see the announcement here). My main focuses on the committee have been in testing for that hard data and in defining our formal risk management approach.

So, the machine came out of storage. I repainted the target with a single red stripe and a couple of coats of polyurethane. Following some discussion on the need for a wider sampling of the society, the machine was packed up and sent out on a World Tour which included visits to the SCA 50-Year Celebration, the 2016 West-An Tir War, and Pennsic 45. Guest scientists collected data and submitted it to be included in the master results collection. The Kingdom of Lochac has also built two clone machines that will be used to collect data in Australia and New Zealand. We changed the questions that we were asking slightly and requested that fencers also supply data for "hard" hits as if someone had stepped in on them and they were unable to completely pull the shot.

At West-An Tir war, the 100-pound scale finally gave up the ghost and broke internally. A replacement was already in hand and was easy to swap in.

At Pennsic 45 we also collected the first data on percussive cut power. To assist with that, I made a small polar fleese cover for the target to provide a little padding and additional friction for the cutting shots.

And, on the first day of testing at Pennsic 45, a high power cut broke the 3/4" thick oak target in half.

It took a couple of days, but a replacement target was made of 3/4" plywood and we continued testing.

The heavy picnic tables that we'd used as a base for Pennsic 43 were not available on the rapier field, so we used a plastic folding table that I had brought. It's light weight required me to rest a fair amount of my weight on the table to avoid having it flip over when the machine was hit. The uneven ground and my weight, resulted in some damage to the table.

Following testing at Pennsic 45, I (again with the help of Jarl Timoch) created a new alternate arm for the machine. The intent is to clip fabric swatches across the open face and test penetration forces of different materials and layer counts under blows from different types of failed blades. No testing has taken place to date and I may need to redesign the arm as the rear post across the testing area may cause problems with accurate measurement of puncture loads. Note that the solid arm used for all of the testing to date was just swapped out and can easily be reinstalled to take more data.

Next: See the Results and Discussion page for the results of the new data collection.